Adaptive, real-time control in a high-mix, temperature-sensitive environment—this was the challenge faced by Rutland Plastics in automating the insertion of M8 brass inserts into plastic assemblies with a heat-staking process.

Adaptive, real-time control in a high-mix, temperature-sensitive environment – this was the challenge faced by Rutland Plastics in automating the insertion of M8 brass inserts into plastic assemblies with a heat-staking process. By using a fully integrated PLC solution with real-time temperature feedback, Rutland achieved superior process stability, high productivity, and future-ready flexibility through a platform built to Industry 4.0 standards.

The Challenge: Temperature-Sensitive Heat-Staking and Servo Motion

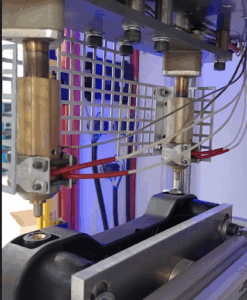

Rutland Plastics needed to automate the insertion of M8 brass inserts into plastic components using a heat-staking process, a critical joining process in manufacturing that uses localised heating and cooling to raise the temperature of plastic components above their glass transition temperature. This allows the plastic to be reformed around inserts, creating a secure mechanical bond without requiring additional fasteners or adhesives.

The most significant challenge emerged from temperature variations in the plastic parts coming from the moulding process. This variability demanded sophisticated control strategies:

- Cold parts required a slower insertion motion and longer dwell times for proper heat transfer

- Hot parts risked melting too far into the component or binding with the heating element

- Throughput: The process must complete within a 15-second cycle time to meet production demands

- A servo-based motion system with real-time temperature feedback and dynamic control logic was essential – far beyond the capabilities of standard pneumatic solutions. Modbus communication was an additional requirement for the cobots that would move and position the inserts and injection-moulded parts.

The Solution: Integrated Application with PLC, HMI, Servo + Motor

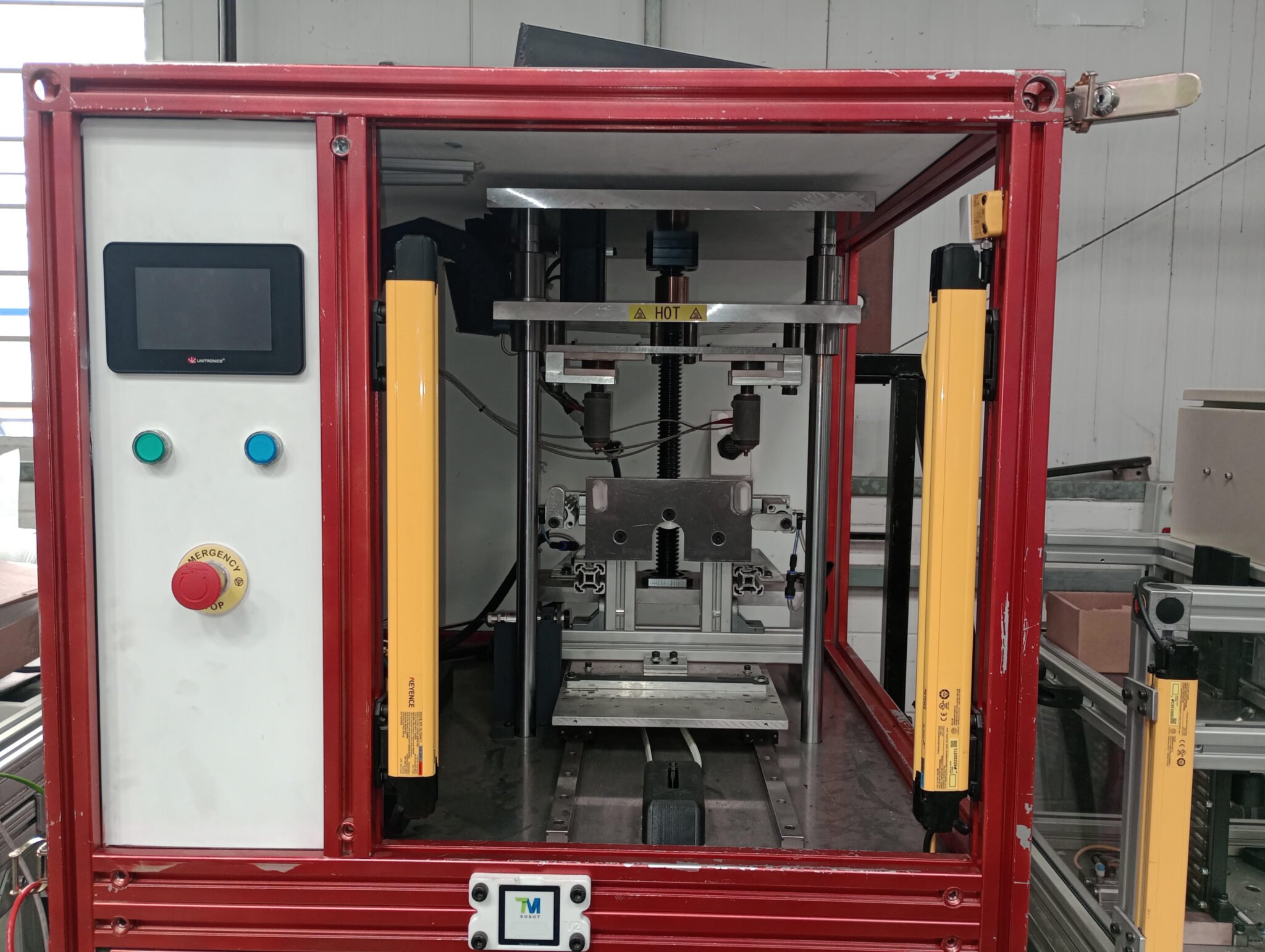

Rutland selected Unitronics and used the UniStream platform to manage the entire application—from motion and temperature control to HMI, cobot communication, and data logging, achieving all project goals:

- 15-second cycle times were maintained consistently across varying part temperatures

- Automated insert placement with reliable engagement mechanisms

- Temperature-adaptive process control with real-time parameter adjustment

- Seamless cobot integration through UniStream’s simple, robust Modbus communication

- Operator-friendly interface enabling easy recipe management and monitoring, System Architecture and Control.

Core Automation Hardware

All components work together transparently, out of the box.

- Controller: UniStream USC-B5-T42 PLC (24 DI, 16 TO, 2 AI, PWM support)

- Temperature Monitoring: UIS-08TC thermocouple module (8 channels for accurate, distributed sensing)

- HMI: USL-050-B05 5” touch display (800x480px)

- Motion System: Unitronics Servo Drives and Motors, EtherCAT networking for precise, real-time axis control

Software

UniLogic: A unified, no-cost development environment supporting PLC logic, HMI design, servo configuration and free motion code, and industrial communications—minimising commissioning time and support overhead.

Key Application Features

- Dynamic Temperature Management: The system incorporates an infrared thermometer connected to the controller’s analogue inputs, providing real-time part temperature measurement. Based on this data, the application loads appropriate motion parameter sets for different temperature ranges, ensuring consistent results regardless of part temperature.

- Multi-Loop PID Control: 4 PID loops maintain precise temperature control of the heating elements, with the UIS-08TC module providing accurate thermocouple feedback. This closed-loop control ensures optimal heating profiles for different part geometries and materials.

- Servo-Based Insertion: Ultra-smooth, programmable motion profiles replaced the variability of pneumatic actuators, yielding lower reject rates and finer process control.

- Advanced Monitoring and Diagnostics: Trend graphs display motor torque during insertion, providing real-time feedback on process quality. The system also uses PWM to control temperature warning LEDs.

- Integrated Recipe Management: Operators can select, edit, and save application “recipes” for different moulded parts using the touchscreen HMI. This capability enables rapid changeover between product lines—supporting high-mix production without any additional programming.

- Seamless Cobot Integration: UniStream’s built-in Modbus communication enables direct interfacing with robotic systems. According to Jamie Hooper, “UniStream has the best Modbus functionality in my experience”.

- Scalability and Future-Proofing: the system’s modular design, comprehensive I/O capabilities, and recipe management system ensure adaptability to future heat-staking applications.

Conclusion: A Unified Platform

With Unitronics’ fully integrated hardware and software ecosystem, Rutland Plastics now achieves:

- Consistent 15-second cycle times across fluctuating ambient and part temperatures

- Superior joint quality and process repeatability

- Robust diagnostics and rapid changeover, enabling higher productivity

- Simple, future-proof integration with collaborative robots and data systems

Jamie Hooper, Rutland’s automation team leader, reported, “The ability to program all the hardware within one programming environment made for a much neater, more efficient programming experience. The servo setup was simple and programming with PLCopen function blocks was effortless.”

By fusing PLC-based intelligence, real-time temperature feedback, and servo motion technology, Rutland’s heat-staking solution sets a benchmark for adaptive, digital manufacturing – demonstrating how unified control platforms accelerate innovation and competitiveness in European industry.